In pursuit of the root cause

Your organization has lost a tender again. A chief engineer left a company on short notice. A number of defective products exceeded the day limit. Projects perennially fail to meet planned time and budget targets. You’ve received a reclamation from one of your customers… Sounds familiar?

The list of situations when the result differs from the desired performance can be easily extended. Some of these issues require known actions to level out immediate negative effects on business, others should be carefully investigated and analyzed to come up with a suitable solution. At the same time, there is an important similarity in such problems — all of them usually have a cause or a set of causes that procure a deviation of an outcome from the wanted one.

Finding the causes of the issue is a challenging task. However, its successful accomplishment makes it easier to identify solutions during the problem-solving process. There is a vast array of methods, tools, and techniques that aim to uncover the causes of problems. They are combined under the common term “root cause analysis” (RCA). Some of them are more general, others are dedicated to specific situations and require a deep understanding of a method and its application area from a problem-solver. Besides the identification of possible causes, RCA tools allow the definition of actions to fix the issue or to prevent it from occurring.

The big domain of qualitative methods can be used as starters during brainstorming sessions and aid in pinpointing issues and formulating the principal problem. Four of them are described below.

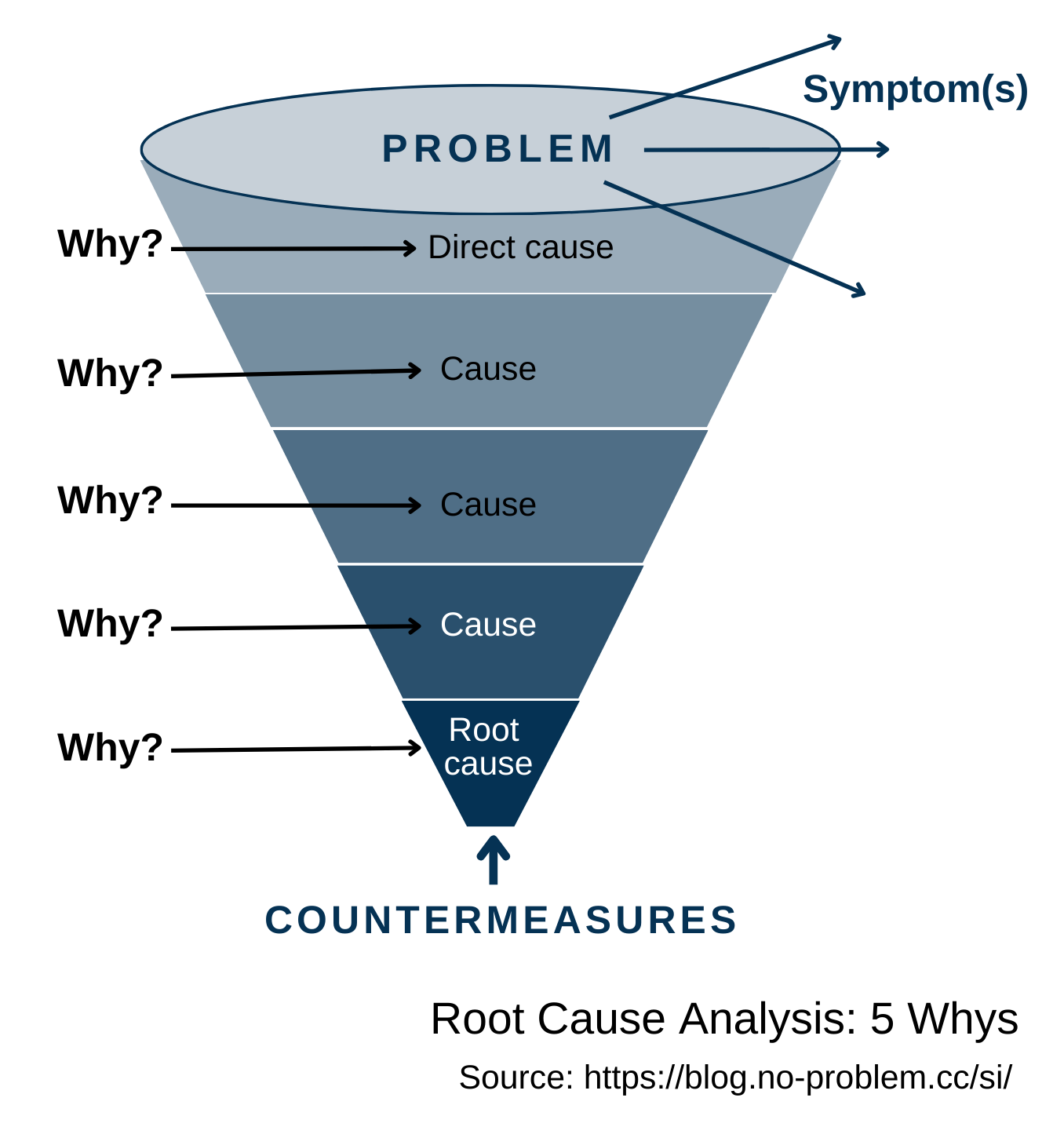

The 5 Whys

This is a rapid and simple technique to identify causes through the exploration of direct cause-and-effect relationships. It was originally developed and applied by the Toyota Motor Corporation. Today, it is a part of standard problem-solving techniques used by Kaizen, Lean, and Six Sigma professionals. The primary goal of this method is to determine the root cause of a problem by five times repeating the increasingly granular “Why?”-question about a problem or process. In most cases, the answer to the fifth “Why?” is the root cause. Sometimes the questioning requires the next Why-iterations to get to the root cause. To perform this analysis, it is necessary to see a problem, obtain the facts, and grasp the situation’s details. A hypothetical application scenario can be the following:

Problem: Reclamations from customers

Q1: Why do customers write reclamations?

A: Because customers are not satisfied with services. Other options: quality of products, project delays, or another fact mentioned in reclamations.

Q2: Why are customers unhappy with our service?

A: Because customers have to repeat their issue from the very beginning after each call handover from one operator to another. Other options: long waiting time on the line, unclear instructions from an operator of a call center, etc.

Q3: Why do operators not capture inquiry details?

A: Because it is written in their instructions that only the inquiry topic must be specified in the tracking system. Other options: inquiry details is not a mandatory field to capture, etc.

Q4: Why is it not mentioned in the instructions that inquiry details have to be captured in the system as well? A: Because there is no dedicated field for it in the system. Other options: to capture details will increase the average time per call, operators are not incentivized by quality of calls, etc.

Q5: Why is the tracking system designed this way?

A: (this answer is to be the root cause of the problem)

It can be clearly seen that the result of this analysis highly depends on the knowledge base of a problem-solver, his ability to avoid reasoning fallacies and dig to the root cause, rather than symptoms. Obviously, different people using it may come up with different causes for the same issue. Therefore, the outcome should be validated. Nevertheless, the 5 Whys is a great brainstorming instrument to seek causes and can be effectively combined with other RCA tools.

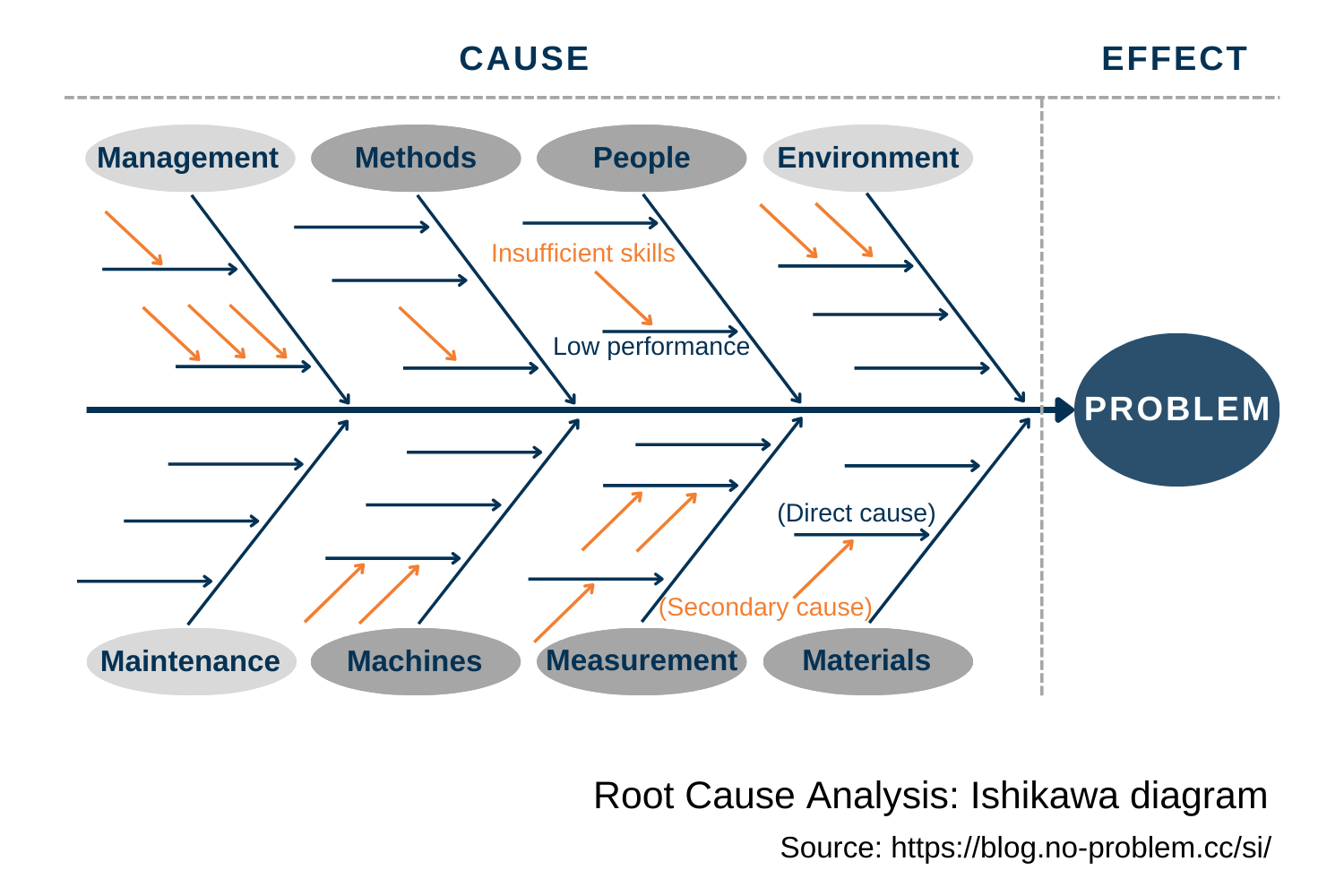

The fishbone diagram

The cause-effect diagram, the fishbone diagram, and the Ishikawa diagram are the titles of the same tool. It is based on the principle of simple causality and aims to identify possible causes of an issue. Using this method during brainstorming sessions encourages team members to generate ideas about likely problem causes and organize them in a systematic manner. To give an impetus to analysis and make collaboration more productive, information is usually grouped into the following categories:

- People/ Manpower — causes induced by anyone who carries out or interacts with different aspects of an issue.

- Methods/ Procedures — the way things are done, whether by written documents or unwritten rules.

- Machines/ Technology — causes summoned by equipment and specifics of applied technologies.

- Measurement/ Medium — matters caused by improper or poorly chosen measurement.

- Materials/ Information — causes that appeared because of defects in raw materials or wrong inputs into processes.

- Environment is the immediate area surrounding the problem, like humidity, temperature, and other essential physical factors or culture, working climate, and so on.

- Management — causes produced by poor leadership and management mistakes.

- Maintenance — issues caused by inappropriate maintenance.

The fishbone diagram originates from the quality domain in a manufacturing environment. In lean production, the 5Ms (Manpower, Machines, Methods, Materials, Measurement) is one of the most utilized frameworks for root-cause analysis. The great adaptivity of this method allows a problem-solver to use it in other organizational areas by expanding or shrinking the number of categories and tuning their meanings to fit the specifics of a business field. The process of creating the diagram includes the following steps:

-

On a whiteboard (physical or one in a collaboration tool) sketch a basic fishbone shape and write a summarized version of the defined problem where the fish’s head should be.

-

Define major categories and their headings. Try to reduce overlap between categories. Draw a fish spine and connectors. Label each connector.

-

Explain categories to the team, brainstorm suggestions, and distribute them into the categories. Suggestions that fit to more than one category are to be duplicated and placed on the respective branches. It is helpful to write ideas on sticky notes (physical or virtual ones) to be flexible in rearranging them across the fish skeleton.

-

To ensure the detailed examination of the problem, use the 5 Whys technique for each category of the diagram.

-

Review the outcome, discuss ideas: placement on the branches, priority, and the probability of being a cause, and make required corrections in the diagram.

-

Assess the branches that have the biggest impact and circle options that are likely to be root causes.

-

Plan further investigations of the marked causes.

This method is commonly applied in a reactive modus to trace the root cause(s) of the existing problem. It can be also used as a valuable add-on for product design to analyze trends and prevent potential pitfalls.

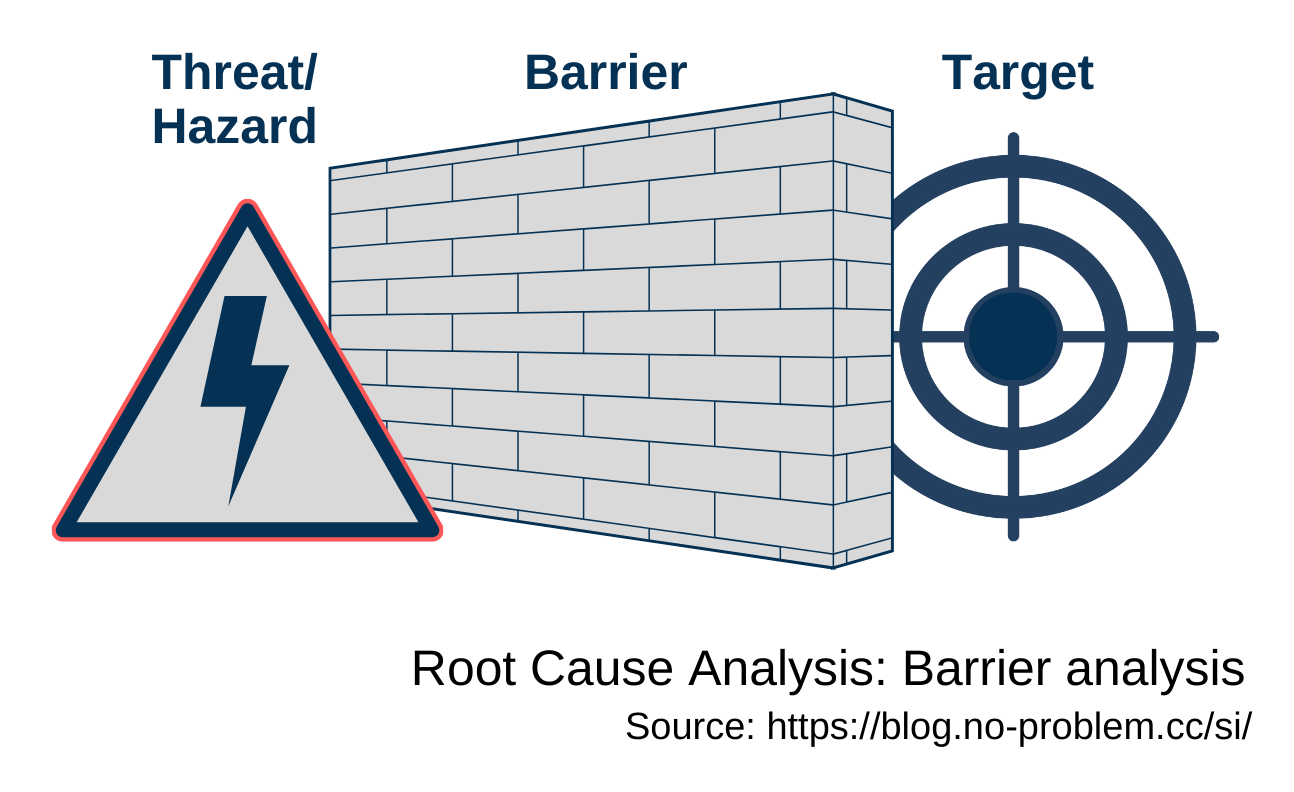

Barrier analysis

This method has a dual purpose: to understand why a problem happened and how to prevent it. Barrier analysis is derived from and commonly applied in health and safety management to reduce workplace injuries. It may also be used for other areas where risk analysis and prevention play an essential role. This is a relatively simple technique that does not require a lot of resources for successful completion. If a problem-solver has a deep understanding of an issue and its environment, the analysis can be performed solo, otherwise, team brainstorming is a better option.

The three key elements of barrier analysis are the target, the hazard, and the barrier. Therefore, this method is also known as Target-Hazard-Barrier analysis.

The target is something that is being selected to be fulfilled or protected (a person performing a job, quality of a product, outcome of a project, etc.). It needs to be maintained under a set of specific requirements.

A hazard is a way to harm the target or a cause that hurts it. Hazards are derived from various categories associated with the workplace (safety, physical, ergonomic, psychological, etc.), business risks (strategic, regulatory, financial, operational, reputational, etc.), or other threats concerning the target.

A barrier prevents a negative effect from occurring and provides control over the hazard. Effectiveness of protection has a lot of variations and depends on types, design, and amount of barriers, the chosen solutions to prevent the problem, defined standards and industry best practices, lessons learned from previous incidents, and so on. A single barrier provides one layer of protection for the target, which is taken as a physical, procedural, or individual action. Sometimes, there is a need for multiple layers to defend against failure.

The reliability of this method can be significantly increased by combining it with other RCA techniques.

The questioning method (5W2H)

It is another efficient brainstorming technique to start problem diagnostics and draft directions for further analyses. The questioning method comprises the three main stages:

- Description of the initial issue.

- Separation of the principal problem from the secondary ones.

- Suggestions on countermeasures.

The iteratively applied tool allows decomposition of an issue and collects precise problems’ descriptions. Systematic questioning addresses a challenge from different angles, intending to reveal the causes. To use this method, the following questions should be answered:

- What (problem description)?

- Who (involved stakeholders)?

- Where (the place/ process)?

- When (the moment, the duration, and the frequency)?

- How (the methods and the manners)?

- How many (the means, the equipment, and the material)?

- Why (the reasons, the causes, and the objectives)?

There is no strict order to answer the questions. If a team cannot provide a specific response for one inquiry, it can be skipped and the next question should be addressed. As the principal problem and its environment become clearer, visibility of other answers grows. To spot details on a granular level, some questions should be repeated in incremental series with a focus on possible solutions.

The simplicity of this method ensures that a facilitator can use general problem-solving skills to guide a brainstorming. Besides defining, analyzing, and mapping a problem the 5W2H is widely used for conflict resolutions, during project planning sessions, and different types of prospecting.

The landscape of qualitative methods is not bounded by the techniques described above. It is continuously developed and enriched by novel approaches and complementary tools. To properly assess and validate findings and strengthen the results of root cause analysis, different techniques should be combined and supplemented by quantitative methods.

Read this article on LinkedIn